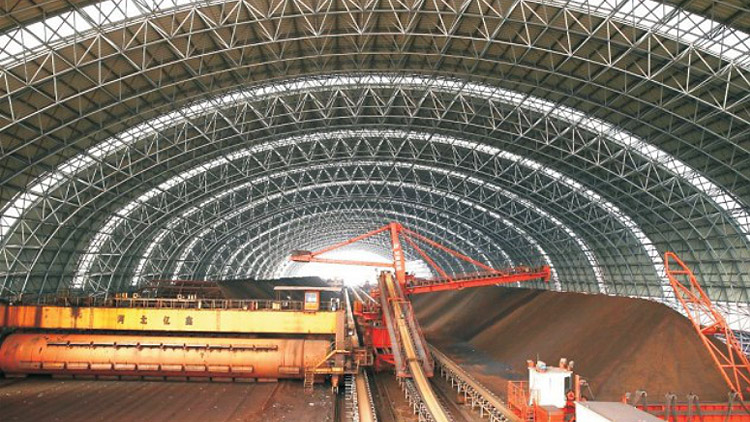

Most domestic stock yard production management and production organization still lag in manual transcription, walkie-talkie communication level, lack of necessary informationization management tools and real time intelligent scheduling system, which will cause delay or tardy scheduling between management the executive, and pose negative influence on material supply, quality and cost. Through equipment status monitoring, stock yard intelligent management and operation intelligent scheduling, stock yard intelligent scheduling management system can manage elaborately product information from the whole process, push forward stock yard production more intelligent and informationized

contact

By using laser coal inventory-making system, material yard in/out belt weigh system and bucket-wheel positioning system

By using gray line, encoder and laser scanner

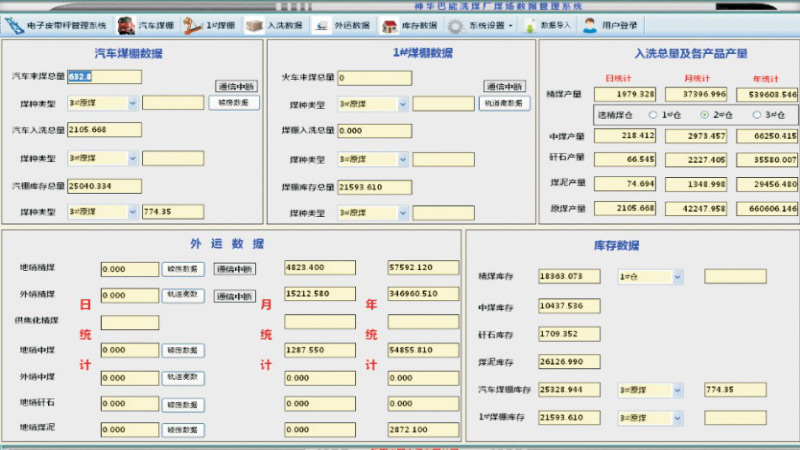

Equipment status monitoring: collect and show all available status data through various ways

Feedstock scheduling: recommend stockpile area according to feedstock type and weight system

Discharge scheduling: recommend material-taking area according to stock-discharging type and weight system

Collect and display the status data of the stacker and reclaimer

Monitor the current real-time position of the bucket wheel by combining travel position

Arrival scheduling: according to the type of feeding and weight system, a good stacking area is recommended

Exit scheduling: According to the type of discharge and weight system

Through equipment status monitoring, stock yard intelligent management and operation intelligent scheduling, stock yard intelligent scheduling management system can manage elaborately product information from the whole process, push forward stock yard production more intelligent and informationized, so as to reduce labor intensity and cost of operators

Through equipment status monitoring, stock yard intelligent management and operation intelligent scheduling, stock yard intelligent scheduling management system can manage elaborately product information from the whole process, push forward stock yard production more intelligent and informationized, so as to reduce labor intensity and cost of operators

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP備20000218號-1business license

Technical Support:Competition network